Details

Information Summary:

It can work efficiently in the vertical, curved, and horizontal inverted parts of the ship.

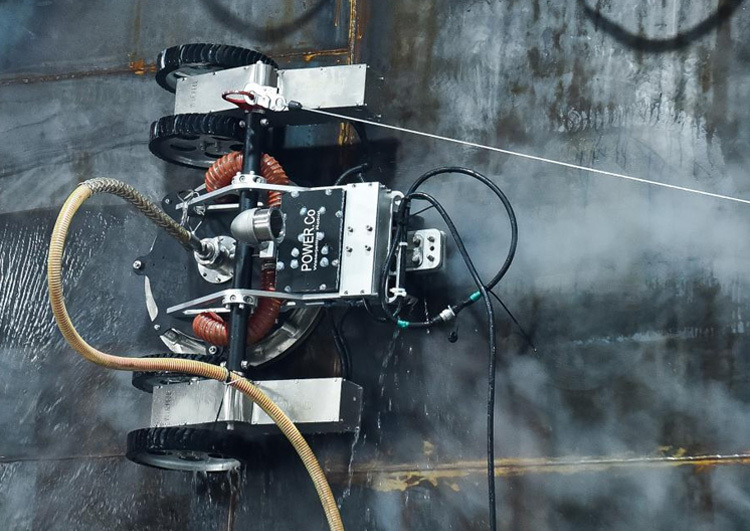

Equipment specially designed for cleaning, paint removal, and rust removal on ship surfaces. It can work efficiently on vertical, curved, and horizontal inverted parts of the ship. Flexible, efficient, environmentally friendly, and safe, it can significantly improve productivity and reduce labor loss. It can be paired with a PW recovery system to recycle all cleaning waste.

PW-RBT ultra-high pressure water jet surface treatment robot system: An innovative force in the industrial field.

With the rapid development of technology, automation and intelligent technology have increasingly become key driving forces in the field of industrial manufacturing. Against this backdrop, the PW-RBT ultra-high pressure water jet surface treatment robot system has emerged, bringing revolutionary changes to various industries with its efficiency, precision, and environmental friendliness.

1. System Overview

The PW-RBT ultra-high pressure water jet surface treatment robot system is an advanced automated processing equipment, mainly used for surface pretreatment and fine processing of metal and non-metal materials. This system integrates ultra-high pressure water jet technology, robotic technology, and intelligent control technology, achieving efficient cleaning, decontamination, rust removal, cutting, and other functions on material surfaces.

2. Technical Features

1. Ultra-high pressure water jet technology: Utilizes the powerful impact of ultra-high pressure water jets to achieve efficient processing of material surfaces without damaging the substrate.

2. Robotic operation: High-precision robots are used for operation, greatly improving work efficiency and operational accuracy.

3. Intelligent control: The system has intelligent recognition and adaptive adjustment functions, allowing for automatic adjustments based on different materials and needs.

4. Environmentally friendly and energy-saving: Compared to traditional processing methods, ultra-high pressure water jet technology is more environmentally friendly, reducing the use of chemical agents and lowering environmental pollution.

3. Application Fields

The PW-RBT ultra-high pressure water jet surface treatment robot system is widely used in shipbuilding, bridges, construction, automotive, aviation, and other fields. In shipbuilding, this system can be used for rust removal and cleaning of the hull surface; in bridge construction, it can be used for the maintenance of bridge steel structures; in the construction field, it can be used for the treatment of concrete surfaces; in the automotive industry, it can be used for fine processing of automotive parts.

4. Advantages

1. Increased production efficiency: Robotic operation greatly saves labor costs and increases production speed.

2. High operational accuracy: The precision of robotic operation allows for tasks in complex environments.

3. Environmentally friendly and energy-saving: Compared to traditional methods, this system is more environmentally friendly and reduces environmental pollution.

4. Wide applicability: Can be used for surface treatment of various materials, meeting the needs of different industries.

In summary, the PW-RBT ultra-high pressure water jet surface treatment robot system is an important technological innovation in modern industrial manufacturing, bringing revolutionary changes to various industries with its efficiency, precision, and environmental friendliness.

Key words:

Cleaning project

Motor Unit

Previous Page

Previous Page

Related News

PW-RBT Ultra High Pressure Water Jet Surface Treatment Robot System

2025-01-23

It can work efficiently in the vertical, curved, and horizontal inverted parts of the ship.

Ultra-high pressure unit exported to Indonesia

2025-01-23

Ultra-high pressure unit exported to Indonesia: A new milestone in technical exchange and multinational cooperation.

2025-01-23

Recently, the highly anticipated Guangzhou Maritime Exhibition opened grandly by the banks of the Pearl River.

2025-01-23

The visit of overseas clients to our factory and the establishment of a cooperation intention is an important milestone in the history of our company's development.